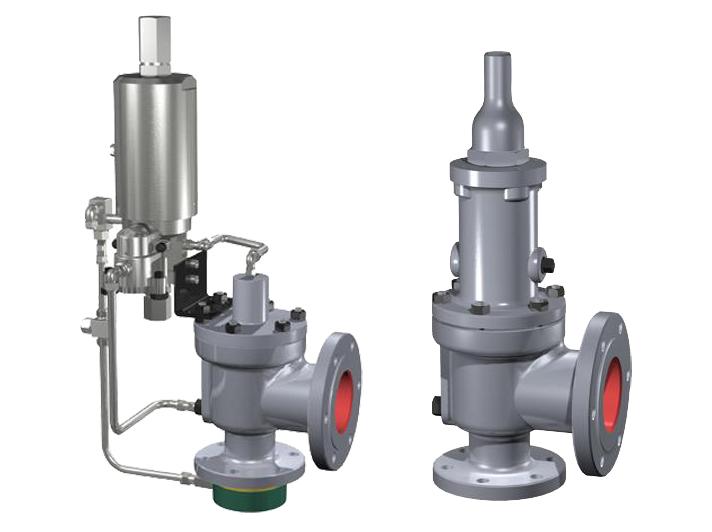

GAMME BAKER HUGHES CONSOLIDATED®

BAKER HUGHES CONSOLIDATED®safety valves are recognized for all applications that require automatic protection against overpressure. They are manufactured by a world leader in this field.

- Spring safety valves for steam generators and boilers up to 650 °C.

- Safety relief valves with spring or pilot for process and protection of production units: air, water, chemicals …

Dimensions: DN 15 à DN 600 depending on model.

Pressure: from 340 mbar to 500 bar and over.

Materials: the combination of different materials like Carbon Steel, Stainless Steel, Alloy C, Monel …. can meet the most demanding applications.

Design and certification: following international standards like API, ASME sections I, III et VIII, DESP 97/23/EC, ISO 4126, GOST, SQLO…

Applications: thermal or nuclear power plants; various industrial sectors including gas, chemical, petrochemical…

Sizing and pricing : please contact us with the characteristics of facilities to protect and process data (fluid, pressure, temperature, flow … )

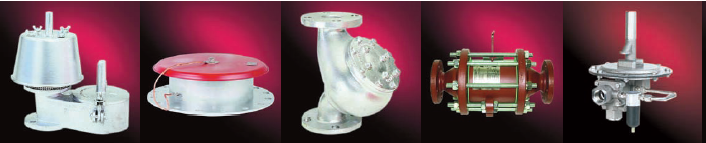

GAMME PROTECTOSEAL®

PROTECTOSEAL® has more than 80 years of experience for safety in atmospheric tanks, vapor control and environmental protection.

PROTECTOSEAL® range of products : pressure vents, vacuum vents, combined pressure/vacuum vents (breather vents), combined vents with flame arrester, emergency vents, blanketing valves.

Dimensions: DN 50 (2″) to DN 600 (24″) depending on model.

Pressure : from 2 mbar (- 2 mbar and below for the vacuum vents).

Material : Aluminum, Ductile Iron, Carbon Steel, Stainless Steel, Alloy C276.

PVC, PVDF, PP, PE, Derakane, reinforced resin, special coating.

Design and certification : following international standards like API 2000, EN ISO 28300, CE, ATEX …

Applications : protection of storage tanks, reactors, vapor recovery units and VOC in the chemical, petrochemical, sugar, bio-gas plants …

Sizing and pricing : please contact us with the characteristics of facilities to protect and process data (fluid, pressure, temperature, flow … )